|

TERRA COTTA & STONE REPAIR WORKSHOPS (7 HRS)

Edison Restoration Products have been in use in Historic and commercial stone, concrete

and masonry restoration for 33 years. Over 4000 custom repair mortar formulations have been developed over that period of time, including sandstone, brownstone, terra cotta, limestone, marble, granite,

brick, stucco, historic concretes and others. Edison Coatings has also developed and manufactures a complete series of accesssory products, including terra cotta glazes, breathable coatings, sealants, adhesives

and weatherproofing/ consolidating treatments.

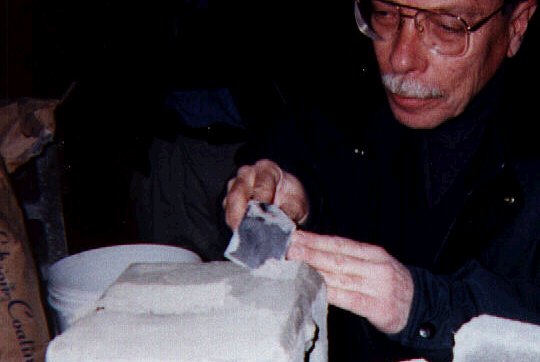

While most restoration craftsmen find working with Edison products

straightforward and intuitive, there is much to be gained from the experience of working with the products in a "hands-on" training course

led by a skilled and experienced instructor. Special techniques and guidelines for their use have been developed as a result of years of on

-the-job field experience, and these will be shared with course attendees. Case studies and visual aids will also be used extensively to illustrate

problem solving, materials selection and potential pitfalls. Emphasis will be on skills and techniques used for exterior applications on vertical and

horizontal masonry. Attendees will be encouraged to participate in "hands-on" exercises, designed to provide an introduction to the working "feel" of these materials.

Course Instructors

John Harry, Restoration Consultant, worked as a restoration contractor for over 20 years before becoming a masonry

restoration consultant for commercial and institutional clients. John's unique combination of practical experience, and

an understanding of building components, materials and technology provide a unique, balanced viewpoint. His focus is on "Practical Building Restoration"

Michael Edison, Chemical Engineer and President of Edison Coatings, Inc., will explain the basic principles of how

custom repair materials work, and the technical guidelines for their selection and application. He has authored a

number of articles and papers on repair materials, and has been a frequent lecturer on the subject at professional

association meetings and conferences. Mr. Edison earned his degree in Chemical Engineering from Polytechnic

University (NY) and an MBA from the University of New Haven. He has been involved in product development,

technical services and project engineering for over 40 years, including the past 34 years since founding Edison Coatings.

Visit the Workshop Registration Site for Additional Details

ADDITIONAL CONTINUING EDUCATION PROGRAMS:

Improvements to Freeze-Thaw, Salt-Scaling and Water Resistances of Masonry Mortar (1 HR)

This presentation reviews the 9-year testing and development program initiated by Edison Coatings

in 2013 to understand and overcome mortar performance problems in challenging exposures. Various additives, treatments and mortar proportioning strategies were explored for both historic

and contemporary mortars, leading to development of an optimized additive that controls air content and hydrophobicity. In addition to improving resistance to water, freeze-thaw and salts, it

simplifies the repointing process, assuring more reliable results.

Terra Cotta & Stone Repair (1 HR)

This seminar illustrates and explores the significance of each of the various materials properties for

stone and masonry repair materials. Through examples and case studies, participants are provided with a framework for project decision-making with regard to required performance and viable

options for material selection. Approaches to large-scale repair, replication of complex glaze finishes, and the special issues revolving around wet terra cotta buildings are also detailed.

Mortar 101: Basic Things You Should Know About Masonry Mortar But Were Confused, Misled or Maybe Just Afraid To Ask (1 HR)

This program reviews the basic components, principals and standards applying to both modern and

historic masonry mortars. Included are the basic chemistry of various types of limes and cements, aggregate selection criteria, proportioning guidelines for modern and historic mortars, applicable

ASTM Standards, approaches to color control and issues in mortar analysis.

The Natural Cement Revival (1 HR)

COLOR SCIENCE IN MASONRY & CONCRETE RESTORATION (1 HR)

This seminar is offered to qualified architectural, engineering and consulting firms involved in

masonry and concrete restoration. The seminar reviews the basics of color science, explores the need for objective color measurement and communication in restoration work, and examines the

various systems which have been used for cataloguing and communicating color information. Issues of color matching, color tolerance, color retention and the practical limitations in controlling

color in "real world" applications are discussed. Methods for optimizing long term color compatibility are presented and illustrated. Strategies and new techniques for obtaining good color

matches are also discussed.

|