RESTORATION LATEXES: RL-1, RL-2, RL-3, RL-4, RL-5

DESCRIPTION:

RL-Series latex modifiers are unique reactive acrylic additives designed to enhance the performance of Portland cement based materials.

When added to cement based mortars, patches, plasters and coatings, RL-Series latex modifiers improve mechanical performance, workability, adhesion and resistance to harsh environmental exposures. They overcome the limitations of conventional acrylic modifiers, eliminating set retardancy, avoiding surface skinning to extend surface working time, and developing superior resistance to water immersion.

RL-1 is a general purpose reactive acrylic modifier which combines excellent mechanical properties with superior workability for trowel-applied mortars, patches, coatings and cement plasters. It provides extended working time, improved hot weather workability, and positive through-setting at any depth.

RL-2 is a superplasticized modifier for use in casting and coating applications.

RL-3 is a chemical resistant, highly reactive latex grade intended for tough industrial and marine exposures, or where high moisture or immersion services are planned.

RL-4 is a high permeability grade, providing levels of water permeability up to 10 times the level of typical building stone and vapor permeabilty more than twice the level of other grades. It is intended for use in applications where high levels of negative side moisture exposure are expected, such as retaining walls, open towers and ruined masonry.

RL-5 is a hot weather grade latex, designed to provide twice the working time at temperatures above 900F.

RL-Series latex admixtures are acrylic based, non-yellowing, irreversible film forming compounds.

PERFORMANCE CHARACTERISTICS:

Mechanical Properties:

Adhesion: RL-Series latex modified mortars develop superior adhesive (tensile) bond strength compared with both unmodified mixes and conventional acrylic modifiers, and retain higher bond strength under immersion conditions. (See Figure 1).

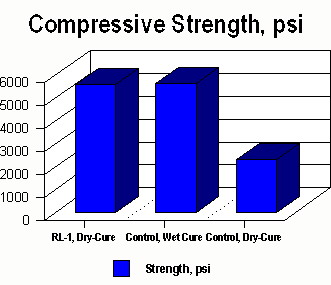

Compressive Strength:RL-Series latex modifiers do not alter compressive strengths of the mortars, patches and plasters to which they are applied. Compressive strength is determined by the mix design of the cement-based material to which the latex modifier is added. Latex modifiers simply assure that mixes will reach the intended design strength without the necessity of wet curing.

Flexural Strength: The polymer-cement co-matrix which forms in acrylic latex modified mortar increases the overall binding capacity of the cement and lowers the Modulus of Elasticity. This results in higher flexural strength. A portion of the gain is due to the synergistic effect of the latex-cement co-matrix, while additional gains are due to the ability of the composite to deform under load and relieve stress.

Cure: Like conventional acrylic latex modifiers, RL-Series modifiers eliminate the need for wet curing under most conditions. The ability to reach design strength under ambient ("dry cure") conditions is even further improved in RL-Series products, which may be dry-cured under hotter, lower humidity conditions than standard latexes.

Tensile Strength:RL-Series modified mortars develop higher tensile strength than either unmodified or standard acrylic latex modified mortars, and they retain their strength better under wet conditions.

Moisture Vapor and Liquid Moisture

Transmission: RL-Series latex modifiers are balanced to provide the optimum

combination of positive moisture vapor transmission, liquid water transmission and weather resistance. 'be results include patches and toppings which do not entrap water

or moisture vapor, while maintaining their ability to withstand wet/dry and freeze/thaw cycling.

Workability:RL-Series modifiers are "non skinning", even in hot, dry conditions, providing twice the working time of conventional latex mortars. They are also "through-setting", providing positive set in any depth, even when still wet. This provides greater installation ease in thick sections and deep castings.

Water Resistance: All RL-Series modifiers incorporate wet adhesion monomers to allow development of high bond strength to wet surfaces, allowing application to wet substrates.

Chemical Resistance:

Although latex-modified cement based repair system cannot approach the levels of chemical resistance offered by Edison polymer concretes such as FLEXI- TOP 550 and 555 and FLEXI-MATRIX 545 epoxy-based repair Systems, RL-3 offers improved resistance to dilute acids and oils as compared with unmodified concrete. In applications such as industrial floor repair prior to coating with more highly chemical resistant FLEXI-GARD 500 epoxy coatings, the use of RL-3 modified mortars offers substantial cost benefits over epoxy mortars. In exterior applications, or where temperatures vary widely, and particularly where repair areas are large and deep, RL-3 modified mortars also offer better thermal compatibility with host concrete substrates than epoxy-based repair systems.

APPLICATIONS & COMPATIBLE MIXES

RL-Series modifiers can be used in a wide variety of applications from architectural repair to industrial flooring.

For architectural repairs, use RL-1 for trowel-applied patches to stone, masonry or concrete using an appropriate Custom SYSTEM 45 mortar. Castings may be made using Custom 45 & RL-2.

For repairs to concrete floors, decks and other traffic surfaces, use RL-1 or RL-2 & Deck-Top 47. For vertical/overhead concrete repair, use RL-1 & SYSTEM 44-V/O-NP.

For marine concrete repair, repairs to fountains, pools, tanks and other water- containing structures, use RL-3 with SYSTEM 44-NP, Deck-Top 47 or Macro-Patch 48.

For additional information and recommendations, consult your Edison Coatings Technical Representative.

FOR COMMERCIAL & INDUSTRIAL USE ONLY.